mutengo wakaderera wefekitori Hunhu Hwakanaka Hwakanaka Hwakanaka, Hushamwari Nezvakatipoteredza, Indasitiri yeMakemikari Bisphenol A

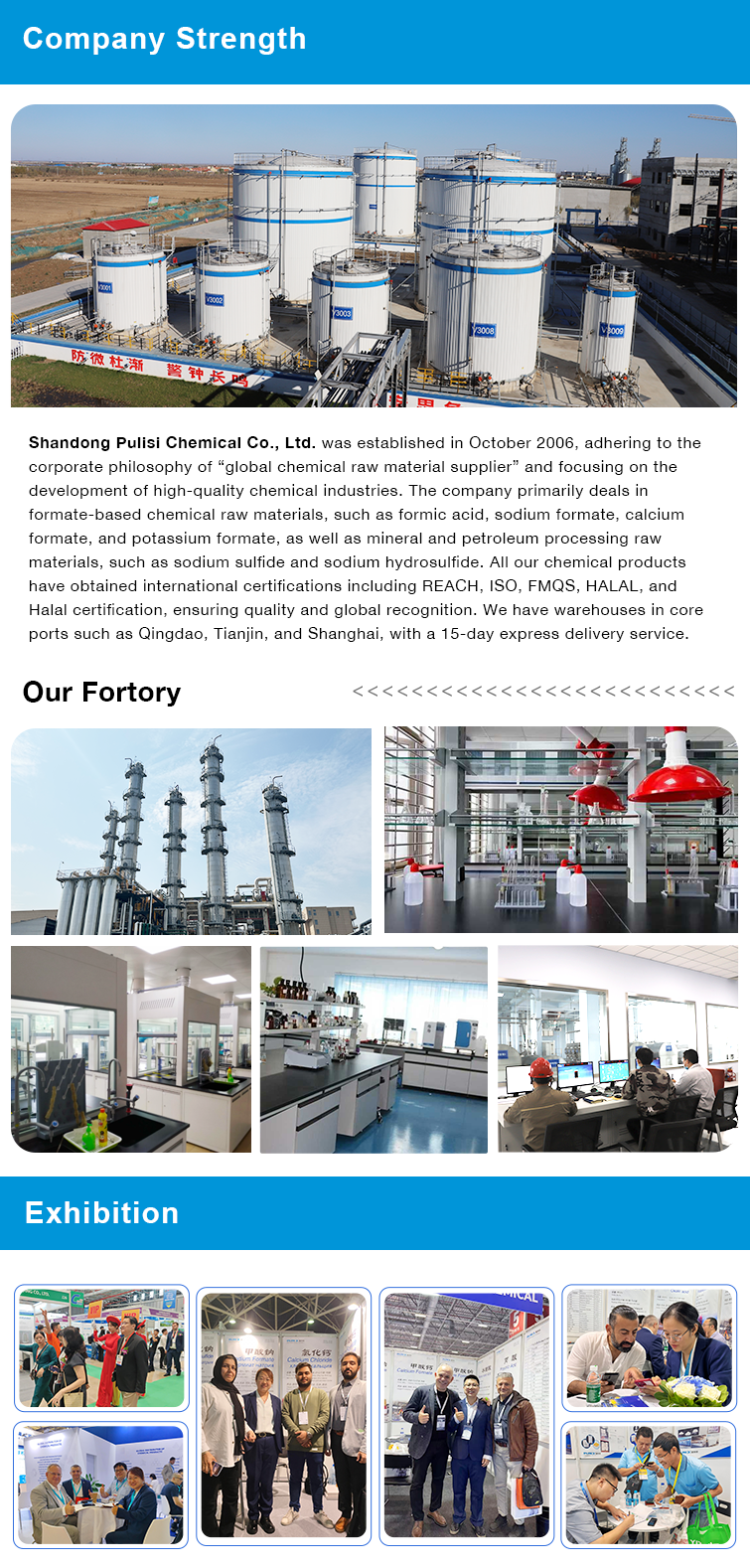

Kambani iyi inotsigira pfungwa yekuti "Iva Nhamba 1 mumhando yepamusoro, vimba nechikwereti uye kuvimbika kuti ukure", icharamba ichishandira vatengi vekare nevatsva vanobva kumba nekune dzimwe nyika nemutengo wakaderera. Indasitiri yemakemikari yemhando yepamusoro, ine hushamwari nezvakatipoteredza. Bisphenol A, Bhizinesi redu rakatovaka boka rine ruzivo, rine hunyanzvi uye rine mutoro wekugadzira vatengi vachishandisa musimboti wekuti vatengi vabudirire.

Kambani iyi inotsigira pfungwa yekuti "Iva Nhamba 1 mumhando yepamusoro, dzika midzi pachikwereti uye kuvimbika kuti ukure", icharamba ichishandira vatengi vekare nevatsva vanobva kumba nekune dzimwe nyika nekushingaira, Chinangwa chedu ndechekuvaka brand inozivikanwa inogona kukurudzira boka revanhu uye kuvhenekera nyika yese. Tinoda kuti vashandi vedu vazvivimbe, vozowana rusununguko rwemari, pakupedzisira vawane nguva nerusununguko rwemweya. Hatitarisiri kuti tingawana pfuma yakawanda sei, asi chinangwa chedu ndechekuwana mukurumbira wepamusoro uye kuzivikanwa nezvinhu zvedu. Nekuda kweizvozvo, mufaro wedu unobva mukugutsikana kwevatengi vedu pane kuti tinowana mari yakawanda sei. Chikwata chedu chichaita zvakanakisisa kwauri nguva dzose.

Mamiriro ekuchengetera bisphenol A anofanira kutenderera pazvinangwa zvikuru zve "kudzivirira kuora, kuona kuchengetedzeka, uye kudzivirira kukanganisa nharaunda".

Mashandisirwo eBisphenol A (BPA)

Bisphenol A (BPA) chinhu chakakosha pakugadzira ma polycarbonates, epoxy resins, uye ma polyester anodzivirira kupisa kwakanyanya. Inoshandiswawo se PVC stabilizer, plastic antioxidant, UV absorber, fungicide, nezvimwewo.

Semusanganiswa unoshanduka-shanduka, BPA inoshandiswa zvakanyanya mukugadzira epoxy resins, polycarbonates, polyester resins, polyphenylene ether resins, uye polysulfone resins. Pamusoro pezvo, inoshanda se stabilizer ye polyvinyl chloride (PVC), antioxidant mupurasitiki, UV absorber, agricultural fungicide, uye anti-aging agent murabha.

Inoshandiswawo se antioxidant uye plasticizer mumapendi neinki. Mukugadzirwa kwezvinhu zvakasikwa, BPA inoshanda sechinhu chakakosha pakugadzira epoxy ne polycarbonate resins, uye inoshandiswa zvakanyanya sechinhu chakakosha chekugadzira zvinhu zvine mamorekuru akawanda, pamwe nekudzivirira kukwegura, plasticizers, uye fungicides dzekurima.

1. Kuvimbika Kwekutumira & Kushanda Kwakanaka

Zvinhu Zvikuru:

Nzvimbo dzekuchengetedza zvinhu dziri muchiteshi chengarava cheQingdao, Tianjin, neLongkou dzine vanhu vanodarika chiuru

matani emari aripo

68% yemirairo inotumirwa mukati memazuva gumi nemashanu; mirairo yekukurumidzira inopihwa pekutanga kuburikidza nekutakura zvinhu nekukurumidza

chiteshi (kukurumidzisa kwe30%)

2. Kutevedzera Hunhu & Mutemo

Zvitupa:

Zvitupa zvitatu pasi pe REACH, ISO 9001, uye FMQS zvinodiwa

Zvinoenderana nemitemo yepasi rose yehutsanana; chiyero chekubudirira kwe100% chekubvisa mitero yemutero

Zvinhu zvinopinzwa kubva kuRussia

3. Hurongwa hwekuchengetedzwa kwekutengeserana

Mhinduro dzekubhadhara:

Mashoko anochinjika: LC (kuona/nguva), TT (20% advance + 80% pakutumira)

Zvirongwa zvehunyanzvi: 90-day LC yemisika yeSouth America; Middle East: 30%

dhipoziti + muripo weBL

Kugadzirisa gakava: nzira yekupindura kwemaawa makumi manomwe nemaviri yekusawirirana kwakabatana nehurongwa

4. Zvivakwa zveAgile Supply Chain

Network yeZvinhu Zvakasiyana-siyana:

Kutakura nendege: Kutumirwa kwemazuva matatu kwepropionic acid kuThailand

Kutakurwa kwechitima: Nzira yakatsaurirwa yecalcium formate kuenda kuRussia kuburikidza neEurasian corridors

Mhinduro dzeISO TANK: Kutumira makemikari emvura zvakananga (semuenzaniso, propionic acid ku

India)

Kugadzirisa Kurongedza:

Tekinoroji yeFlexitank: Kuderedzwa kwemutengo we ethylene glycol ne12% (zvichienzaniswa nedhiramu rechinyakare)

kurongedza)

Calcium formate/Sodium Hydrosulfide yemhando yekuvaka: Mabhegi ePP akarukwa asingapindi hunyoro e25kg

5. Maitiro Ekuderedza Njodzi

Kuonekwa Kwemagumo:

Kutevera GPS panguva chaiyo yekutumira zvinhu mumidziyo

Mabasa ekuongorora evamwe vanhu pazviteshi zvekuenda (semuenzaniso, kutumirwa kweacetic acid kuSouth Africa)

Vimbiso yeKutengesa Mushure meKutengesa:

Gadziriso yemhando yemazuva makumi matatu ine sarudzo dzekutsiva/dzokudzoserwa mari

Zvishandiso zvekutarisa tembiricha zvemahara zvekutumira magaba e reefer

Kunyangwe huwandu hwese hwekugadzira hwemafekitori aya panguva iyoyo hwaisvika matani angangoita 7,000 pagore, huwandu hweBisphenol A BPA hwaingosvika matani 3,000 pagore, izvo zvaingove zvekuzadzisa zvinodiwa zvekugadzira ma epoxy resins avo kana ma polycarbonates. Pakanga pasina BPA yekutengeserana. Nekuda kwezvinodiwa zvekugadzira ma resins emhando yepamusoro, matani asingasviki 1,000 eBisphenol A BPA aiunzwa gore rega rega achishandisa mari yekune dzimwe nyika yakachengetwa panguva iyoyo. Nekuwedzera kwekuchinja nekuvhurwa, mabhizinesi mazhinji emataundi akatanga kugadzira ma epoxy resins mushure ma1980, uye huwandu hweBisphenol A BPA hwakawedzera gore negore. Pakazosvika 1994, huwandu hweBisphenol A BPA hwaisvika matani angangoita 20,000 zvichienderana nehuwandu husina kukwana.